Robots. Efficient, yes, but also costly and complicated?

Not anymore - meet Leap AI.

Founded by CEO Ben Stuart and CTO Ben Bamford, Leap AI is a UK-based robotics business that is addressing two of the key challenges for food & drink businesses right now: spiralling supply side costs and the UK’s chronic labour shortage.

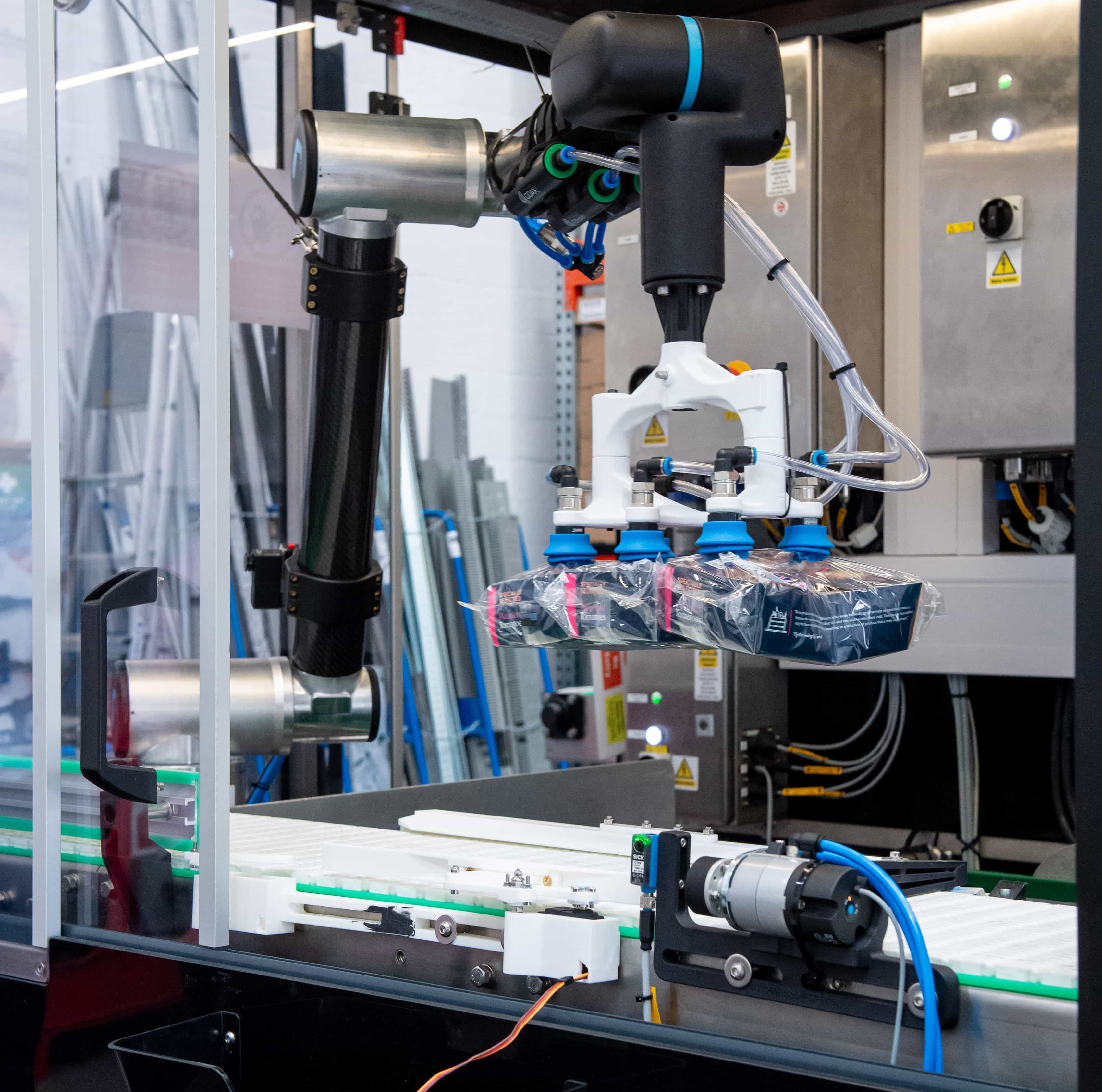

Leap’s groundbreaking PikPak system automates packing for food & drink manufacturers. Instead of a person at the end of a production line packing bags of salad into a tray, the PikPak does exactly what it says on the tin. It picks up the packets of produce - be it fennel, tomatoes, avocadoes – and packs it neatly into trays.

The result? A member of staff now free to take on a more valuable role within the business, and a significantly more efficient process.

Leap AI’s robotics can help businesses to reduce the cost per item packed by up to 70%. They’ve helped companies to increase throughput without having to employ more staff. And they’re delivering these benefits at a significantly lower cost than most robotics systems. Leap aims to achieve a return on investment within 18 months for most customers.

In a sector where labour shortages are a cause of significant lost productivity, and food & drink manufacturers are struggling to maintain margins amidst the increasing costs of energy, raw materials, and labour, this is transformational.

Affordable, accessible, adaptable

Leap’s affordability is thanks to its broad capability. Ben Stuart explains, “Rather than rely heavily on third parties for core elements of the system like robot hardware and software, we’ve built these components ourselves, giving us greater control and flexibility. This has certainly not been the easy path but it means we can now pass the cost and flexibility benefits directly to our customers!”

Leap’s deep AI capability also allows it to offer enhanced quality control. It can train models to verify that products have been packed correctly into the tray or identify any defects in the packaging. “We realised that companies rely on people for much more than just packing – they’re often the last line of defence to ensure that only great products make it to customers” explains Ben. “With AI we’re able to rapidly build some of these checks into the product via vision systems”.

Leap’s in-house software development also makes their system very flexible. The team can tailor the software to each customer’s bespoke needs, and easily modify or add new programmes over the air so the robot can adapt and grow as the customer’s requirements do.

A trusted relationship

The “all under one roof” approach is a benefit that Leap itself enjoys through its relationship with Johnston Carmichael.

Ben Bamford, CTO, had worked with Johnston Carmichael on a previous venture in the Oil & Gas industry. The JC team now works with Leap in a number of areas, led by Client Relationship Partner, Raemond Jappy - from year-end accounting and tax, to R&D tax relief, to EMI share schemes. As Ben Stuart notes, “You want to get these things done well and done quickly. Having Rae and the team there for advice on a variety of topics has been tremendously helpful. Splitting it across different firms slows things down and that's not what you want as a fast-moving scale-up.”

The R&D tax relief work has of course been key for Leap, helping manage cash flow whilst the business invests significant sums into its tech, and EMI schemes have been an important factor in recruitment and retention.

But the real value of the Johnston Carmichael relationship isn’t just good technical advice. Ben says, “Over the years we've built a trusted relationship with Johnston Carmichael. We've gone through multiple twists and turns and when we've needed support and answers fast, JC has always been there for us.”

Having originally started out as an Oil & Gas business, Leap was forced to pivot in 2020, which you can read more about here. This was a challenging time for the business and the team needed advisers they could rely on. “Responding to challenges quickly is really important and you can only do that if you've got a solid relationship,” says Ben.

Johnston Carmichael’s extensive network in the Food & Drink sector has also been beneficial in helping Leap reach even wider audiences of potential customers, investors, and referrers, led by Adam Hardie, Johnston Carmichael’s Business Development Partner and Head of Food & Drink.

Pioneering the future

By making automation accessible to more businesses in the food & drink sector and helping solve its two key challenges, Leap is helping create a more sustainable future for the industry.

The team of 30, based across the UK, now works with businesses from Fife to Kent. The business recently closed a significant investment round to fund the next phase of its growth, as it continues to break new ground. Leap is continuing to invest in its AI capability, leveraging generative AI to transform the way people interact with robotics.

A new product is also in the pipeline that focuses on intelligent individual piece-picking, automating the packaging of items before they’re packed into trays by the PikPak. “We see this as a key growth area for the business and we’re looking forward to launching this product next year”, explains Ben.

For Ben, every installation of a Leap system is as exciting as the first. “Seeing new systems installed and operating on customer sites, delivering value is the best part of my job,” he says, “as well as the consistent feedback we receive on the calibre of our team and service quality. We have incredibly dedicated people that are committed to amazing service and always doing the right thing. Having that validated by customers makes me immensely proud.”

Our specialist Food & Drink team has the skills, insight and networks to help your business thrive. To find out more about how we can support you, get in touch with our experts.