Pivoting for success: from painting oil rigs to packing produce

When life gives you lemons, make lemonade. When life gives you a pandemic, make a transformational impact on the Food & Drink industry.

In 2020, after spending two years developing an advanced autonomous robot, Ben Stuart and Ben Bamford of Leap AI were riding high and poised to take on significant strategic investment to fund the commercialisation of pioneering robotic technology.

Being based in Aberdeen, the Oil & Gas industry was a natural fit for Leap and their industrial robots were designed to blast and paint oil rigs and platforms.

Their plans, however, were disrupted by the onset of the COVID-19 pandemic. “The turmoil in the oil price meant the planned raise fell away. At the same time, a cooling of VC enthusiasm for Oil & Gas focussed plays made raising capital for the intended use case very challenging,” explains Ben Stuart, CEO of Leap AI. “By the summer, with limited runway we were faced with a ‘pivot or die’ moment.”

“It was both the most challenging and most exciting period of my career,” recalls Ben. “We had built a super team and a broad robotic capability spanning hardware and software. What we needed was a new problem to solve that had scale potential and that we could address quickly.”

A problem sought; a problem found

Fortunately, Leap’s enterprising team was up to the challenge and identified that there was a significant gap in the market for an accessible, affordable robotics company in the Food & Drink sector.

“We visited every type of food manufacturer you can imagine and heard time and time again that labour shortages and increasing costs were huge issues,” explains Ben.

Leap knew that their robots could solve these problems, by automating packing for food manufacturers, freeing up employee time to do other more value adding jobs and improving efficiencies. “The challenge for the industry was the cost of existing solutions which typically required an ‘integrated approach’ involving multiple vendors – we spotted an opportunity to leverage our technology to deliver a fully integrated solution comprising proprietary hardware, software and vision systems to offer greater flexibility at a lower cost,” says Ben.

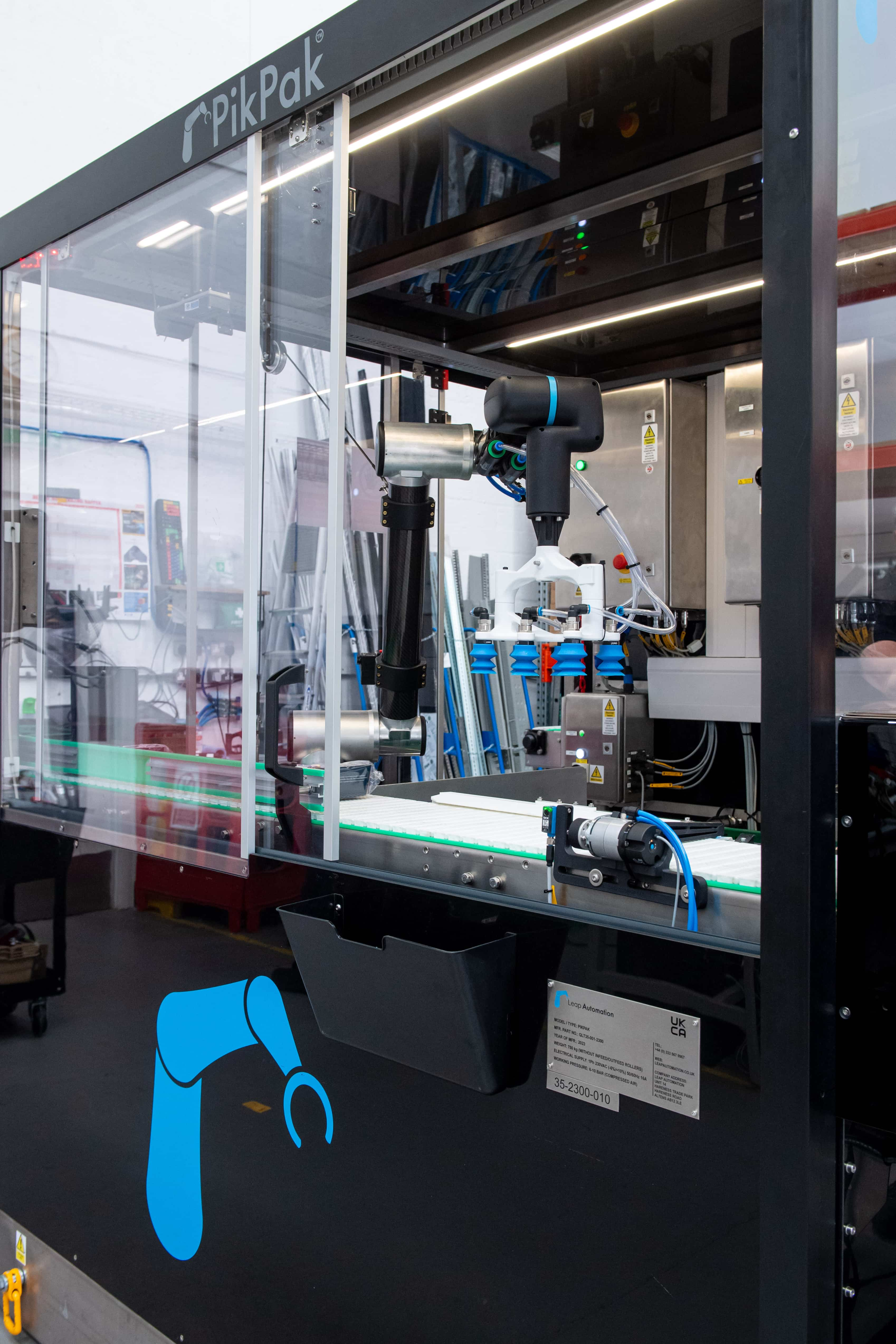

Enter the Leap PikPak, which picks up packages of produce from production lines and packs them into trays and pallets.

“Leap AI is demonstrating that this approach can bring the benefits of robotic automation to companies of all sizes – we don’t want robotics to just be the preserve of big companies that operate 24/7,” explains Ben. “Our systems are even delivering compelling paybacks to companies working single shift patterns.”

Leap’s technology also overcomes the usual barriers to robotics – their cost and their flexibility. Leap’s unique integrated system, which you can read about in our full case study here, makes it significantly more affordable than most robotics, as well as more adaptable.

“We heard lots of stories about people that had invested significant sums of cash in a robotic system that couldn't adapt to changes in their product lines or requests from their end customers. We wanted to deliver something that was easy to use, easy to adapt and could develop with our customers,” Ben says.

And that’s exactly what they did. Leap launched their first PikPak system in 2021, working with Fresca Group, a UK-based supplier of fresh produce. Three years on, Leap is now working with seven businesses across the UK, supported by Johnston Carmichael as trusted advisers.

Leap AI is demonstrating that this approach can bring the benefits of robotic automation to companies of all sizes.

Ben Stuart

CEO, Leap AI

Creating an impact

In what is a very challenging time for the Food & Drink sector, as our latest Food & Drink Industry Report illustrated, 47% of the survey respondents reported that automation could be a viable solution, but responses also indicated that the necessary investment was prohibitive. Leap’s innovation is creating opportunities for more businesses to capitalise on automation and reap the benefits of it.

By eliminating the obstacles to robotics, Leap is helping food & drink manufacturers achieve better operational and cost efficiencies, which in turn results in better margins.

The wider impact of this goes far beyond figures on a balance sheet. The performance of the Food & Drink industry has a direct impact on its consumers – all of us. As Ben explains, “The ability for robotics to drive significant efficiencies within the food sector can help companies to give us a more resilient food supply chain.”

And if anyone knows about resilience, it’s Leap AI’s team – a prime example of how to turn a setback into an opportunity, not just for themselves but for a whole sector.